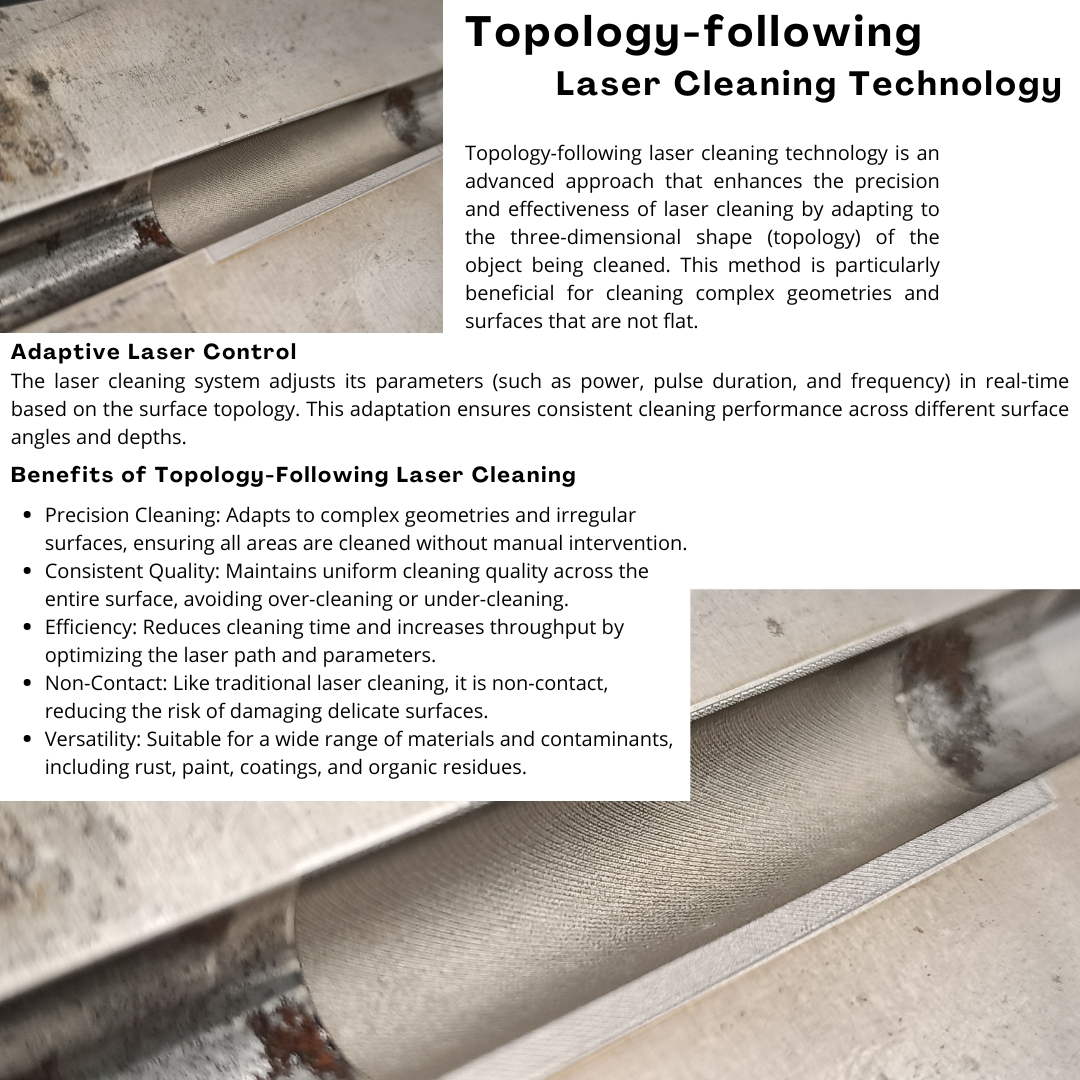

Topology-following Laser Cleaning Technology

Topology-following laser cleaning technology is an advanced approach that enhances the precision and effectiveness of laser cleaning by adapting to the three-dimensional shape (topology) of the object being cleaned. This method is particularly beneficial for cleaning complex geometries and surfaces that are not flat. Adaptive Laser Control The laser cleaning system adjusts its parameters (such […]

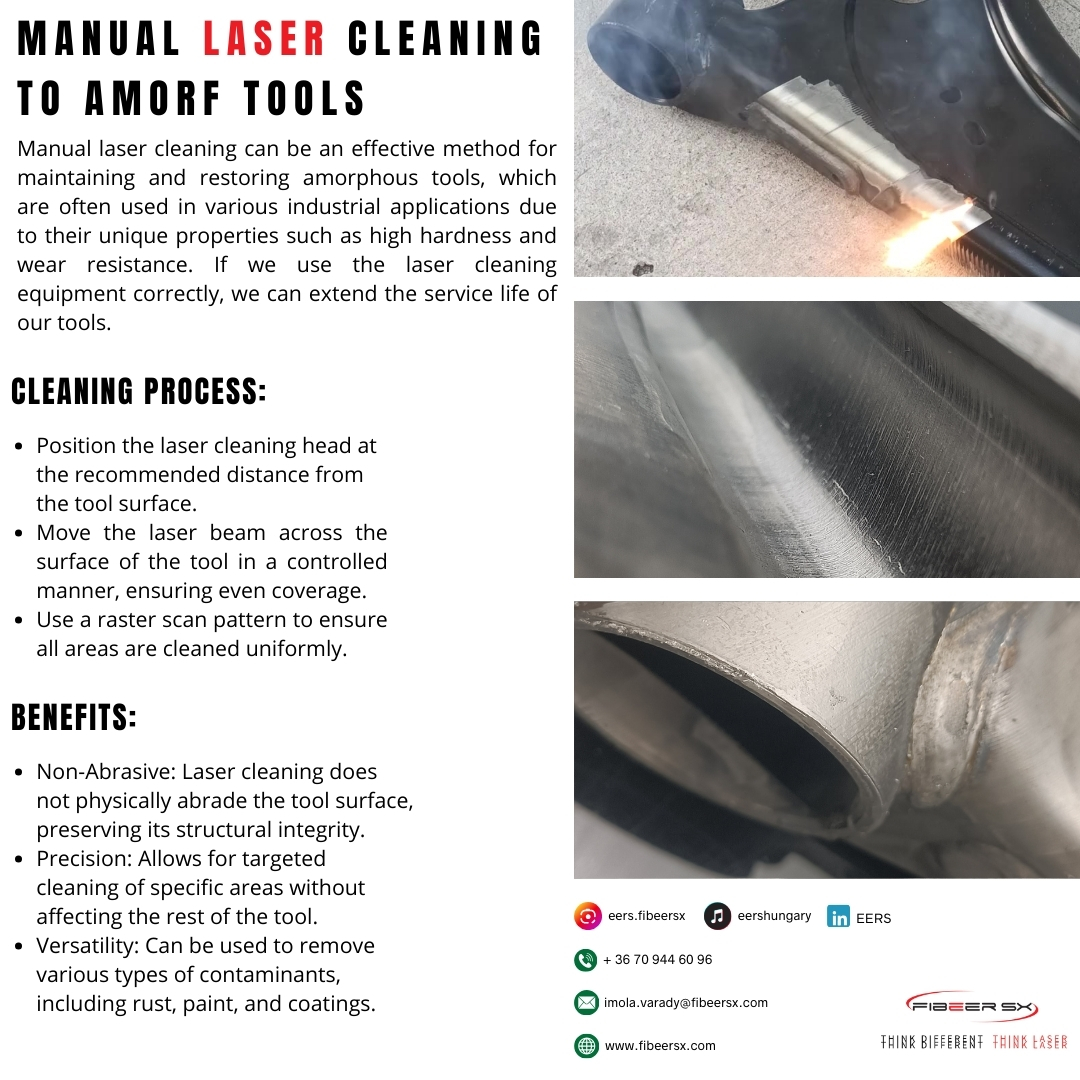

Manual Laser Cleaning to Amorf Tools

Manual laser cleaning can be an effective method for maintaining and restoring amorphous tools, which are often used in various industrial applications due to their unique properties such as high hardness and wear resistance. If we use the laser cleaning equipment correctly, we can extend the service life of our tools. Cleaning Process: benefits:

Mini QR Code

The production of small QR codes with laser technology is one of today’s most modern and effective methods, which offers innovative solutions in many industries. The use of laser technology is not only beneficial in terms of accuracy and speed, but also enables the precise machining of various materials. detailed miniature marking Lasers are capable […]

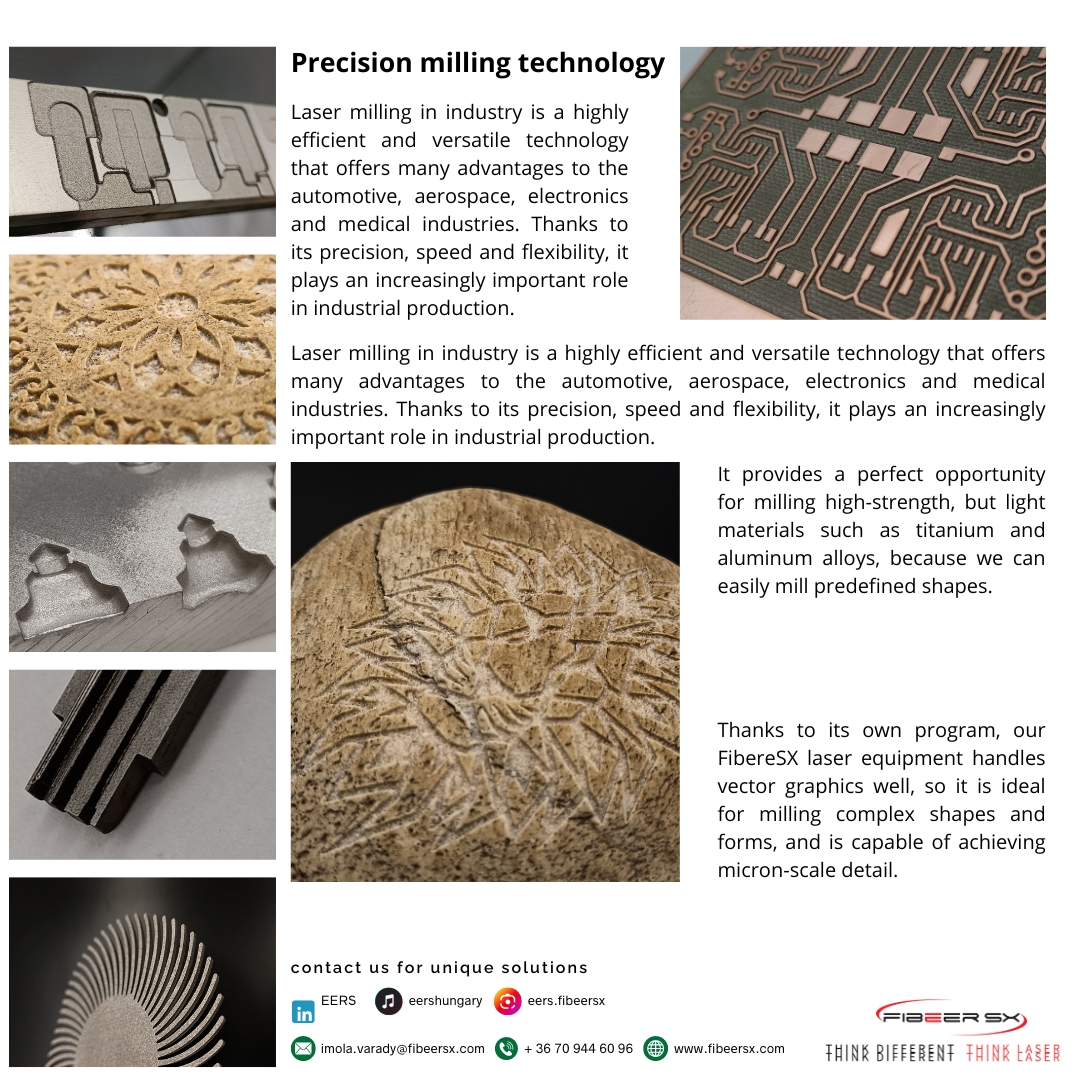

Precision Milling Technology

Laser milling in industry is a highly efficient and versatile technology that offers many advantages to the automotive, aerospace, electronics and medical industries. Thanks to its precision, speed and flexibility, it plays an increasingly important role in industrial production. Laser milling in industry is a highly efficient and versatile technology that offers many advantages to […]

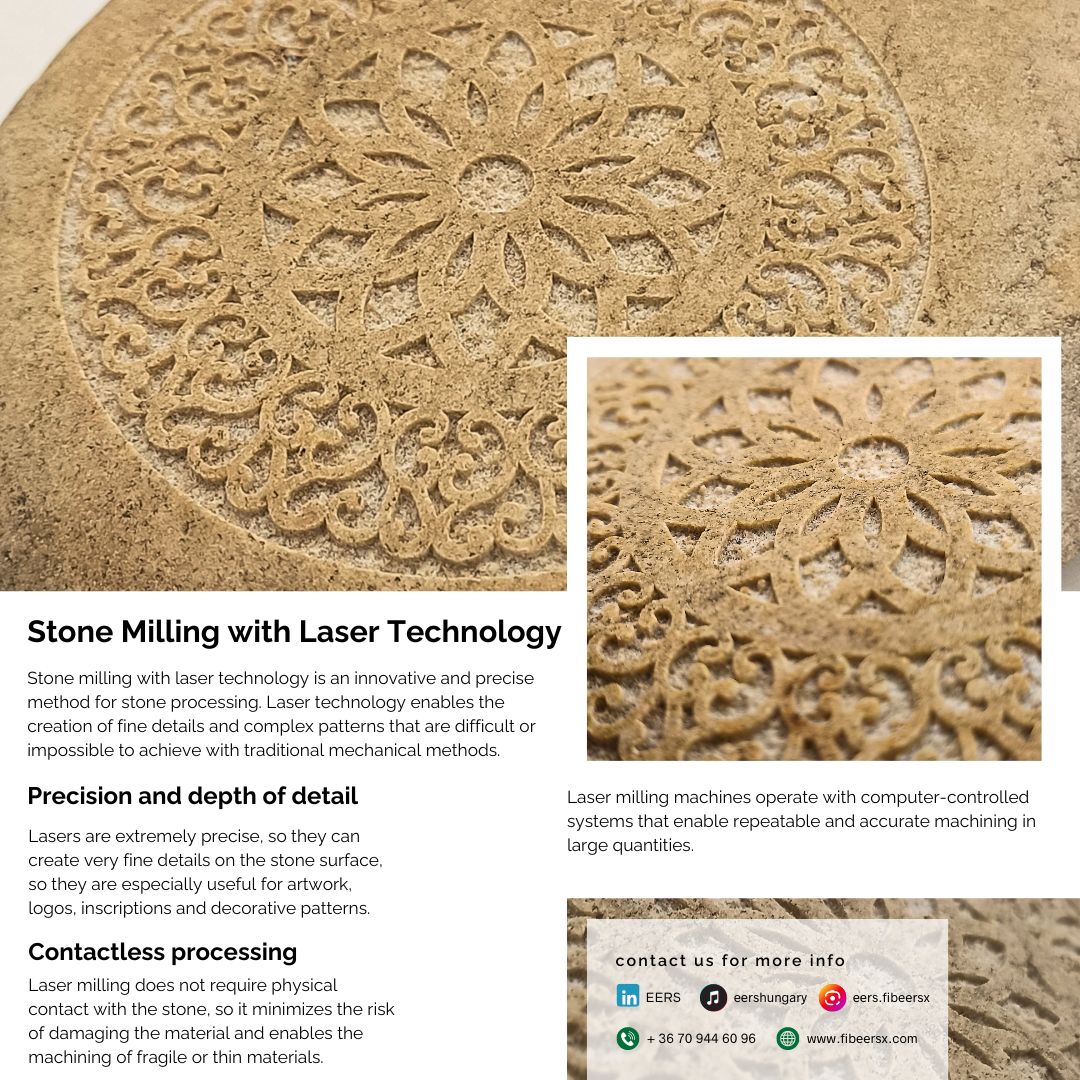

Stone Milling with Laser Technology

Stone milling with laser technology is an innovative and precise method for stone processing. Laser technology enables the creation of fine details and complex patterns that are difficult or impossible to achieve with traditional mechanical methods. Precision and depth of detail Lasers are extremely precise, so they can create very fine details on the stone […]

Engineering Support

Our team of experts is at your side from the initial steps to help you realize the project. As a first step, we recommend a consultation, where we discuss the details of the project and, if necessary, test our technology on the product so that we can provide you with the perfect solution. When we […]

Integration & Installation & First Start-up

Our engineers provide assistance in everything during the integration, installation and commissioning of the machine after purchase. integration During integration, we help you set up communication and data exchange between different systems, as well as adjust everything according to the environment. Installation During the installation, we set the appropriate parameters on our own Windows-compatible software, […]

Precision PCB Cutting with Laser Technology

Precision PCB cutting with laser technology is an advanced and efficient method that offers many advantages over traditional mechanical cutting techniques. precision and contactless technology Laser cutting is accurate, fast, and allows intricate designs to be cut out without the need for physical contact, minimizing mechanical stress and the chance of damage to PCBs. Advantages […]

Laser Welding in Car Industry

Minimal heat effect During laser welding, the heat effect zone (HAZ) is very small, which minimizes material deformation and possible damage. This is especially useful when working with thin materials such as body parts. Efficiency Laser welding is faster than many traditional welding methods, increasing production speed and reducing production time. Accuracy and precision Laser […]

Plexi Cutting and Marking with Laser Technology

Laser cutting plexiglass, also known as acrylic, is a popular and effective method for creating precise and clean cuts in this material. Laser cutting has many advantages over traditional mechanical cutting methods, including superior edge quality, intricate detailing, and minimal material waste. Cutting speed: Cutting speed must be balanced with laser power to achieve a […]

Precision Laser Welding

Precision laser welding equipment are special tools designed to perform fine and precise welding tasks. Precision laser welders are able to work with very tight tolerances, enabling the welding of small and sensitive parts. These devices introduce minimal heat into the material, which reduces the risk of deformation and damage to the material. Precision laser […]

Multifunctional Laser Technolgy

Thanks to our unique development, lasers are already capable of performing more tasks than ever before. Thanks to the precision, speed and versatility of modern laser technology, it offers effective solutions in many areas, be it industrial, medical or scientific applications. Technology: welding marking cleaning cutting milling surfacetreatment