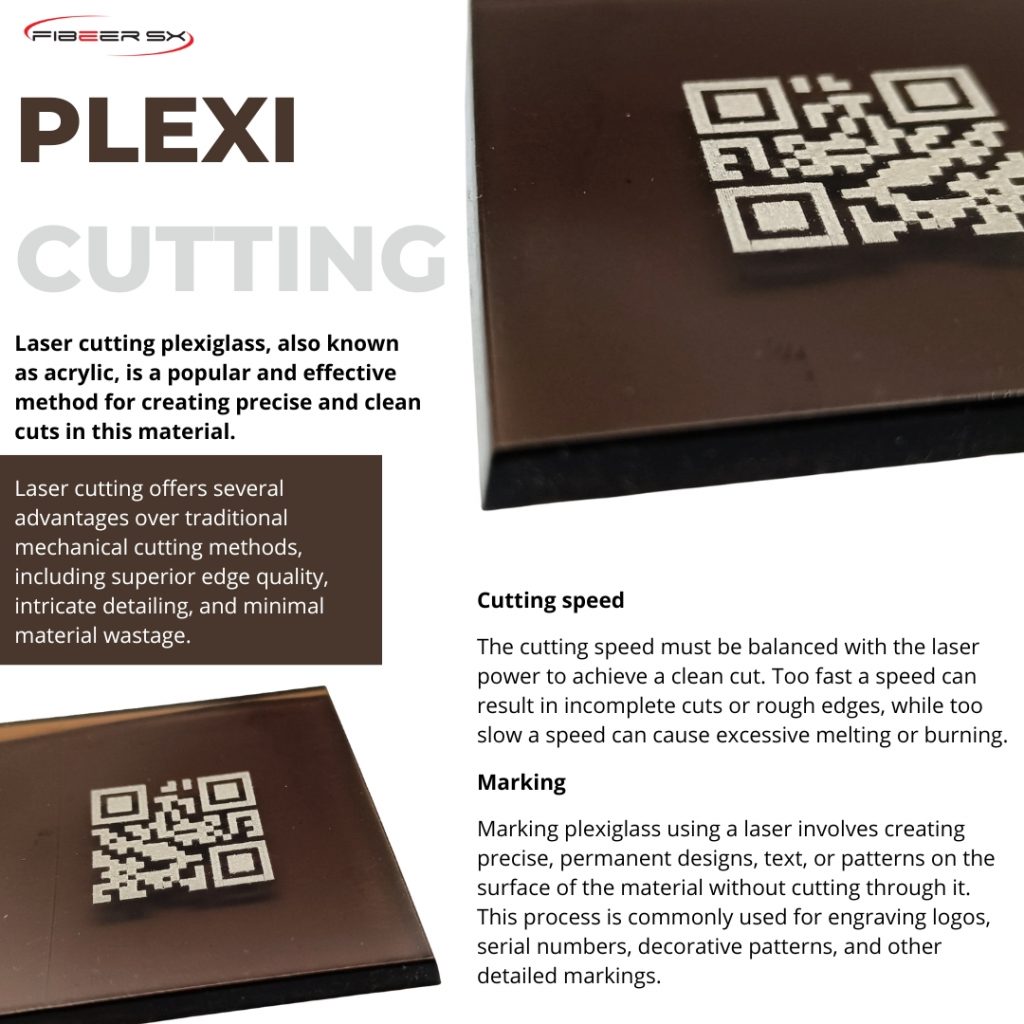

Laser cutting plexiglass, also known as acrylic, is a popular and effective method for creating precise and clean cuts in this material.

Laser cutting has many advantages over traditional mechanical cutting methods, including superior edge quality, intricate detailing, and minimal material waste.

Cutting speed:

Cutting speed must be balanced with laser power to achieve a clean cut. Speeds that are too high can cause incomplete cuts or rough edges, while speeds that are too slow can cause excessive melting or burning.

Marking

Marking plexiglass using a laser involves creating precise, permanent designs, text, or patterns on the surface of the material without cutting through it. This process is commonly used for engraving logos, serial numbers, decorative patterns, and other detailed markings.

Laser cutting of Plexiglas is an efficient and precise method that is widely used in various industries, such as labeling, model making and production of unique parts, automotive parts. Proper setup and handling of the laser cutter can result in high-quality cuts with minimal material loss and reduce the need for additional post-processing.