Advantages of Fibeersx

FibeersX offers cutting-edge solutions in laser technology with several advantages that cater to industrial needs. Advanced Laser Solutions: Multifunctional laser devices designed for cleaning, welding, cutting, marking, and engraving, ensuring high precision and efficiency. Customizable Equipment: Modular designs that can be tailored to meet unique client requirements, ensuring flexibility for diverse industrial applications. Sustainability: Energy-efficient […]

unique laser development

Thanks to our advanced laser development, we offer near-endless variations in functionality and application. Our innovative approach ensures that our laser systems are not only versatile but also highly adaptable to a wide range of industrial needs. Test request form What Makes Our Laser Systems Unique? Our dedication to continuous improvement and customization makes us […]

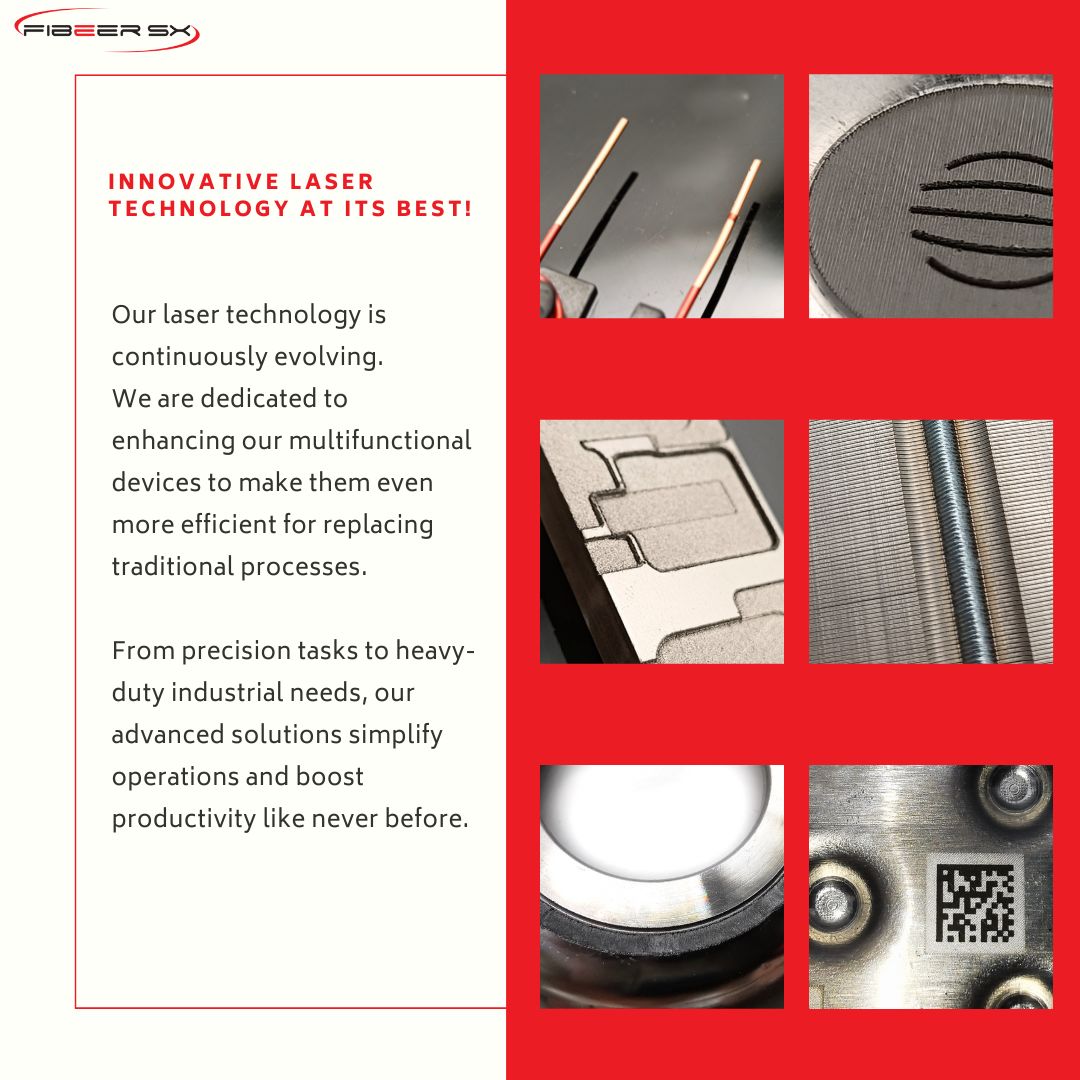

Innovative Laser Tecchnology

Laser technology represents a transformative leap forward in industrial applications, offering unmatched precision, efficiency, and versatility. At its core, laser technology leverages focused light energy to perform tasks with extreme accuracy, making it a game-changer across multiple industries. Test request form Future Enhancements in Laser Technology Innovation in laser systems is a continuous process. Upcoming […]

Advantages of Laser Cleaning for Rust Removal

Laser cleaning is a revolutionary technology for rust removal and surface preparation, offering numerous advantages over traditional methods like chemical cleaning, sandblasting, or abrasive scrubbing. 1. Non-Abrasive and Surface-Friendly Preservation of Material: Unlike sandblasting or grinding, laser cleaning removes rust without damaging the base material. Precision: It allows selective cleaning, targeting specific areas without affecting […]

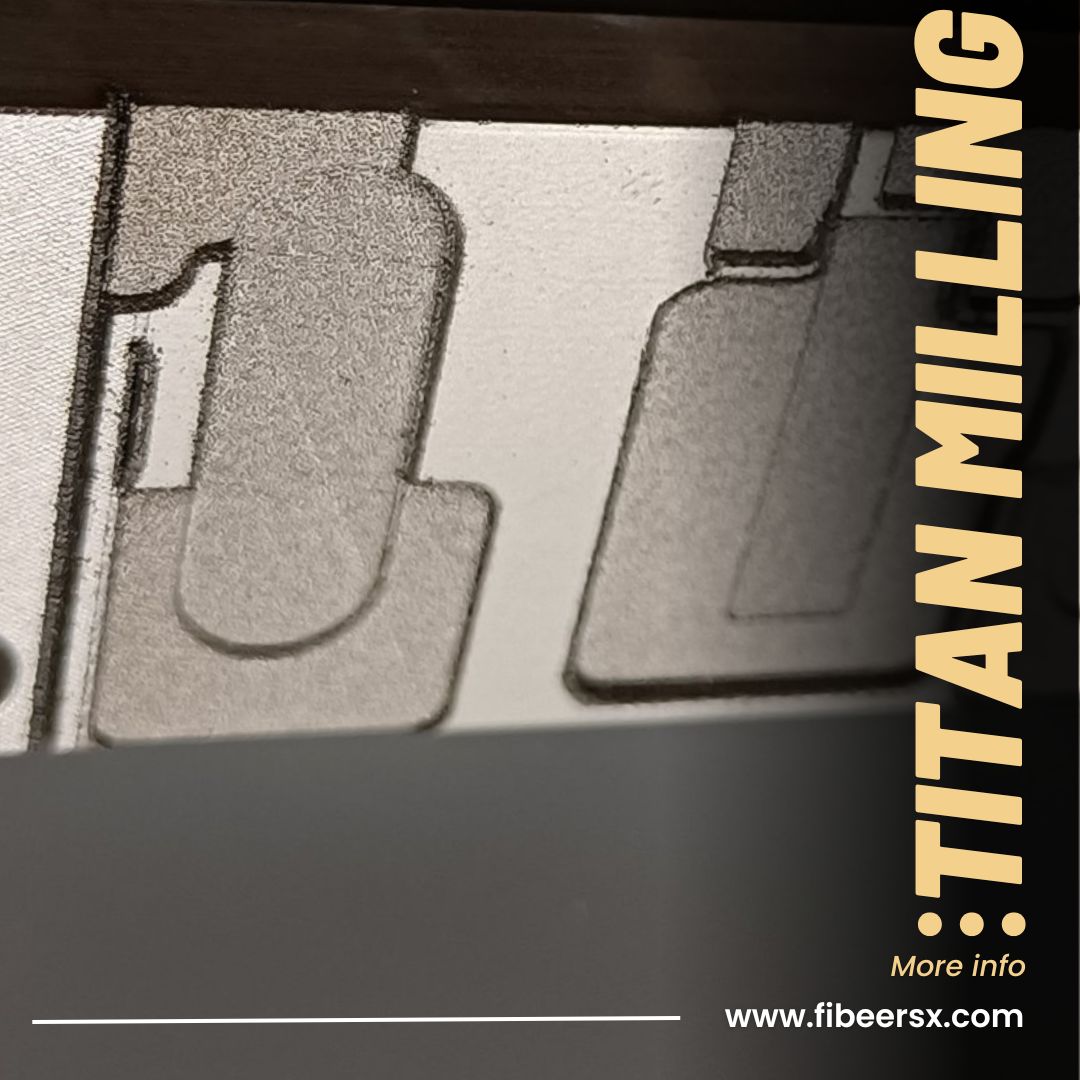

Laser milling offers significant advantages in manufacturing

Laser milling offers significant advantages in manufacturing, particularly due to its versatility in materials and applications. Unlike traditional milling, laser milling can operate without direct contact, allowing it to handle a variety of materials, including rubber, titanium, metal alloys, and aluminum. Here are some of the main benefits of laser milling Material Flexibility: The precision […]

FibeerSX Services

Our modular laser equipment is designed to meet unique and customized requirements. Built to integrate seamlessly into automated production lines or workstations, our lasers are CE-certified and compliant with the specific demands of our clients. We consistently enhance our products and services, facing even the most challenging tasks with confidence. In addition to top-quality laser […]

Laser milling of titanium is a specialized process

Laser milling of titanium is a specialized process that combines the benefits of laser technology with the unique properties of titanium. Traditional milling techniques, while effective, encounter challenges with titanium due to its hardness, heat resistance, and reactivity with cutting tools. Laser milling offers a solution to these issues, providing precise, non-contact processing with several […]

Laser Cutting and Surface Treatment

Multifunctional laser technology has transformed industrial applications by combining processes like cutting, marking, engraving, and surface treatments within a single system. This approach allows for streamlined production, reducing the need for multiple machines and enabling versatile functionality across diverse industries, such as automotive, aerospace, electronics, and medical device manufacturing. Precision and Speed: Laser cutting offers […]

Better Adhesion Result

In contrast to polished surfaces, microribs created with laser technology provide increased adhesion. The fine structures created with the help of laser technology increase the roughness of the surface, which contributes to the stronger and more durable adhesion of various materials, such as adhesives and sealants, to the surface. This method is particularly beneficial during […]

Advantages of laser cleaning over traditional methods

The fundamental task of industrial cleaning is to remove contaminants from surfaces, which often include rust, oil, glue, resin or sealants. Traditional cleaning methods, such as chemical treatments, sandblasting or dry ice cleaning, have been used in industry for a long time. However, these methods often produce large amounts of waste, are expensive and have […]

lasers in industrial processes

The use of lasers in industrial processes significantly simplifies and improves production workflows. Laser technology offers high precision, durability, efficiency, and eco-friendliness, making it an ideal solution for modern industrial processes from manufacturing to maintenance. Laser Marking and Engraving for Long-Term Traceability: Laser marking and engraving ensure that identification markings, such as serial numbers, barcodes, […]

The advantages of laser engraving compared to traditional methods

The advantages of laser engraving compared to traditional methods such as inkjet printing and dot embossing are significant due to several key factors. Request Catalog In terms of durability, laser engraving is a timeless marking solution that will not fade or wear away over time, unlike ink-based methods such as inkjet printing, which are subject […]