Laser Surface Treatment

Laser resurfacing has become increasingly popular in recent years in a variety of industries, including medicine, manufacturing, and beauty. This technology offers many advantages, the most important of which are the following. Precision and controllability One of the biggest advantages of laser technology is precision. Laser beams enable extremely precise treatment of materials and surfaces, […]

Multifunctional Laser

Multifunctional laser technology is a truly versatile and powerful tool that is widely used in various industrial applications because of its ability to integrate multiple capabilities into a single system. This integration offers significant benefits in terms of efficiency, accuracy and flexibility. Milling Laser milling uses a laser to remove material from the workpiece in […]

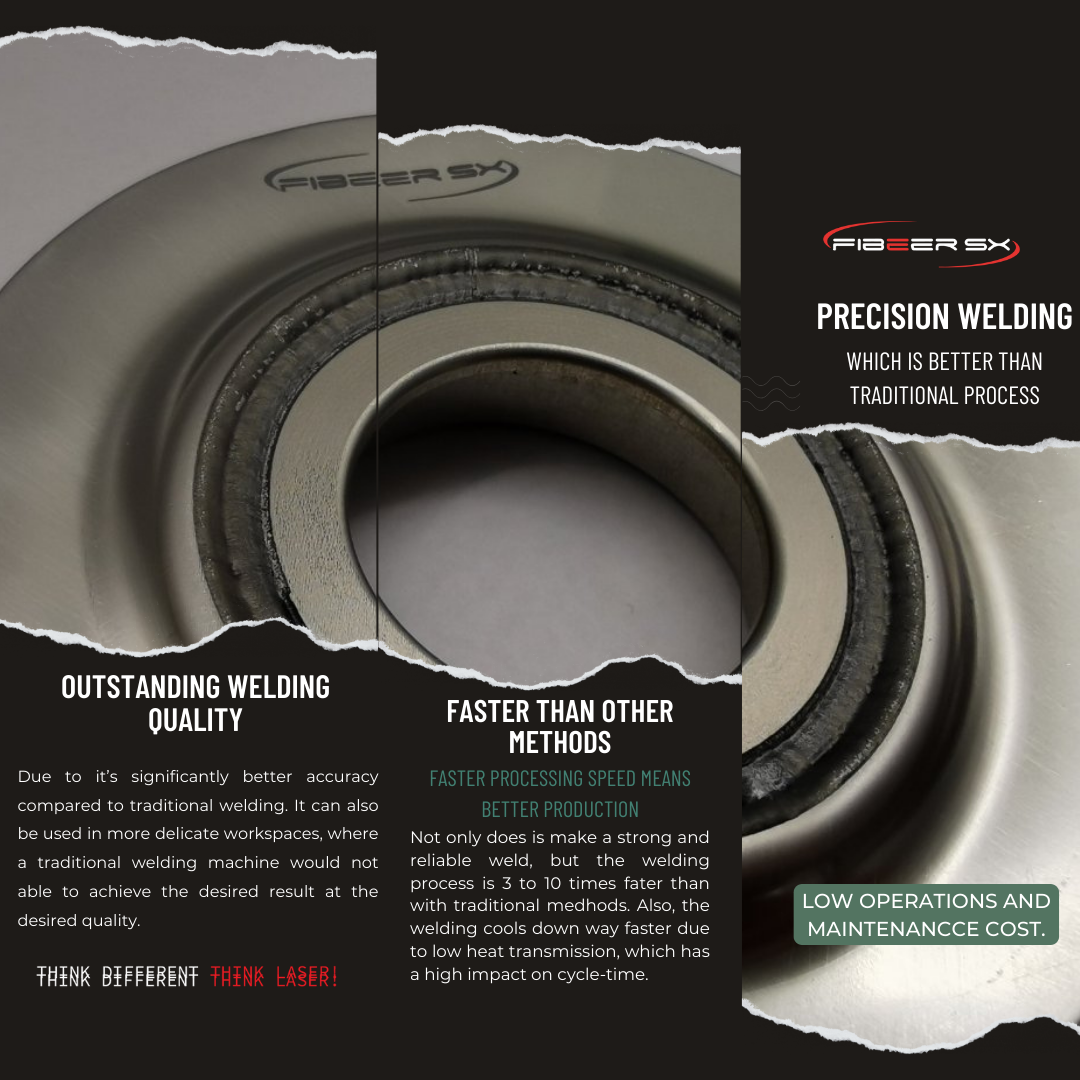

Why Our Welding Systems Outperform Traditional Methods ?

In today’s fast-paced and ever-evolving industrial landscape, the quest for efficiency, quality, and innovation is unending. At the heart of many manufacturing processes lies welding. While traditional welding methods have served the industry well, our company is proud to introduce a groundbreaking line of welding systems that are not only more advanced but significantly superior […]

Support for Partners

The first priority for us is that our partners are satisfied, so in addition to our high-quality products, our services and support are comprehensive. Request CallBack Our company is committed to the continuous support of our partners from the initial steps to full integration. Consultation and planning We work with our partners from the very […]

Unique Developments and Integrated Applications

Thanks to continuous improvements, these laser systems offer improved functions, and we custom-build our equipment for each project. Multi-functional: Advanced systems can perform multiple tasks such as marking, cutting and cleaning using a single laser device with adjustable parameters. Of course, this also depends on the material, but if it can be solved, our engineering […]

Future Technology

Thanks to the unique developments, our partners can use the lasers to perform several tasks. in addition to unique developments, unique support is also important to us we provide a 4-year guarantee for our partners we help with integration and commissioning in addition to on-site consultation, we also provide on-site training Future technology in the […]

Traditional Milling vs. Laser Milling

Both methods have their own advantages and disadvantages, which should be considered depending on the task, material and desired end result. Below I will detail the main differences between the two technologies. Laser milling operation Laser milling uses a laser beam that emits concentrated heat in the form of high-energy light. Laser technology is non-contact, […]

Cleaning Jigs

A safe solution for a closed workstation with sensors thanks to their outstanding accuracy and speed thanks to our automated laser cleaning machines an ideal solution for cleaning JiGs. A very important feature is that the surface remains intact during laser cleaning, in contrast to a traditional one cleaning process, this is not guaranteed. Save […]

Many Sides of Laser Cutting

Precision laser cutting is an efficient process that allows us to cut out clomplex shapes from the raw material. We can provide accurate micron cutting result by specifying the exact parameters, as the process is fully automated. Cable Stripping When cutting cables, layer-by layer removal possible, so we can provide users with much more precise […]

July Tests

We weren’t bored during the summer either, and we took part in many exciting projects. I have brought you a few examples from our work in July so that you can gain an insight into the activities and results of the past month. PAINT REMOVAL IN EFFIFIENT WAY High removal efficiency. With a laser cleaner, […]

Precision Laser Cutting

Precision laser cutting is an essential technology in modern manufacturing, offering unparalleled accuracy and versatility. Benefits Versatility: Can cut a wide range of materials and thicknesses. Quality: Produces clean cuts with smooth edges, reducing the need for additional finishing processes. Automation: Can be integrated with CAD/CAM systems for automated and repeatable cutting processes. Reduced Waste: […]

PCB Milling with Laser Technology

The use of laser technology for PCB (printed circuit) milling is becoming increasingly popular as it offers many advantages over traditional milling techniques. Primarily, laser milling provides exceptional precision and detail, allowing the creation of very fine patterns and lines. In addition, the process can be faster, especially for small series or unique prototypes, significantly […]