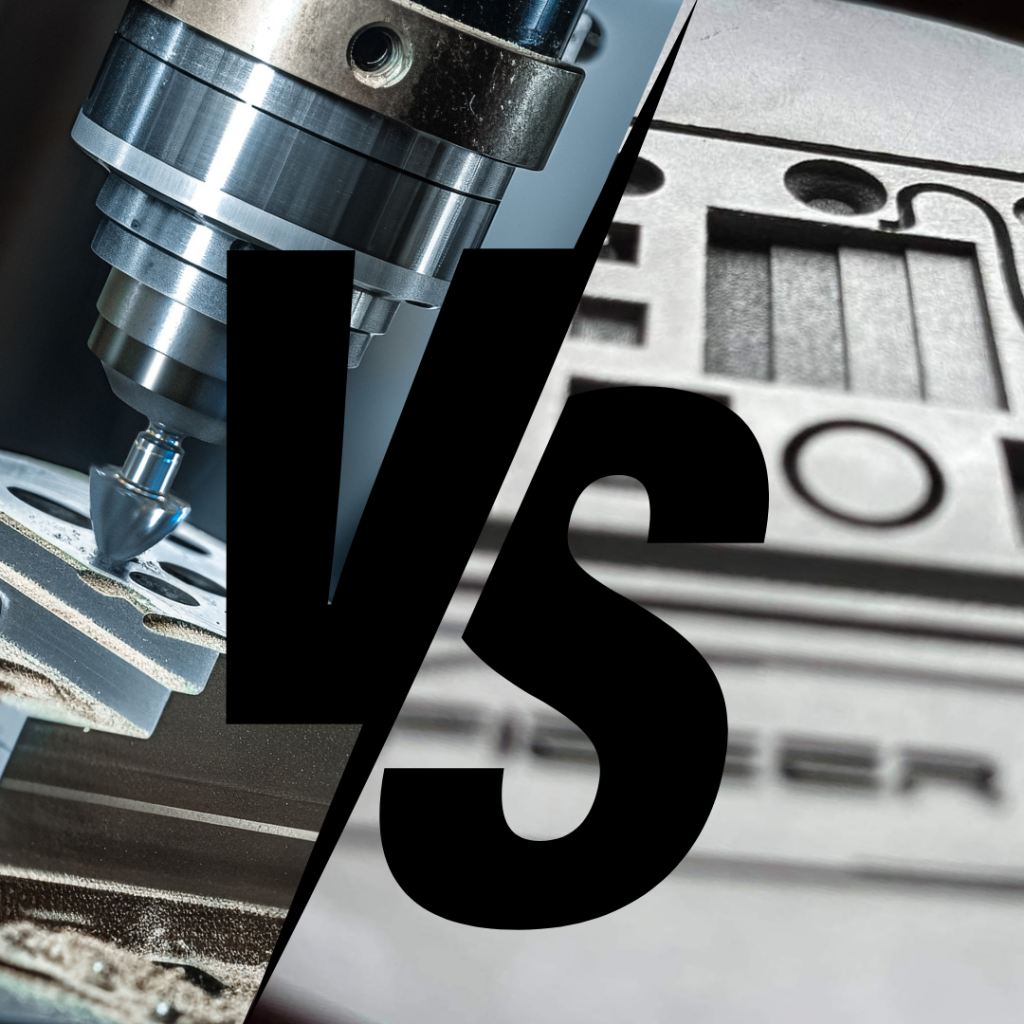

Below I will detail the main differences between the two technologies.

Laser milling operation

Laser milling uses a laser beam that emits concentrated heat in the form of high-energy light. Laser technology is non-contact, so there is no physical contact between the machining tool and the material.

High precision: Excellent precision and detail is achieved, which is especially useful for delicate patterns and complex shapes.

Wide range of materials: A variety of materials can be machined, including metal, plastic, wood and glass.

Speed: Machining can be done at high speed, especially for thin materials.

Traditional millling

Conventional milling uses rotating cutting tools to remove material. The cutting tool makes direct contact with the material, physically cutting it.

Powerful processing: It can work with great power, so thick materials and harder materials can be easily processed.

Less precision: Due to mechanical wear and tool wear, the precision of traditional milling can be cheaper than that of laser milling.

Loss of material: It may result in a greater loss of material due to the chips generated during the milling of the material.

Slower: Machining speed is generally lower, especially for complex shapes and thin materials.