Laser cleaning in contrast to traditional cleaning processes

Energy-saving and environmentally friendly cleaning process. Traditional cleaning methods, such as sandblasting or solvent solutions, require significant energy consumption and have a negative impact on the environment. The advantage of the laser over traditional cleaning is that there is no need to use solutions or other materials.

It is an ecologically neutral, economical and practical choice. Laser cleaning has countless advantages over traditional surface cleaning methods that help work processes. The stricter environmental protection rules and the increasing quality requirements can represent significant burdens for the various manufacturing industries, which can influence the price, demand and supply of products in the long term and this affects competitiveness.

Laser cleaning is not only an environmentally friendly process, but also involves only a one-time investment cost. With continuous maintenance, the service life of the equipment increases. It will pay for itself in a short time, as there is no need for chemicals and yield materials, so the corresponding storage and transport costs of these do not have to be taken into account. In addition to all this, the energy consumption is also much more favorable compared to traditional machining machines.

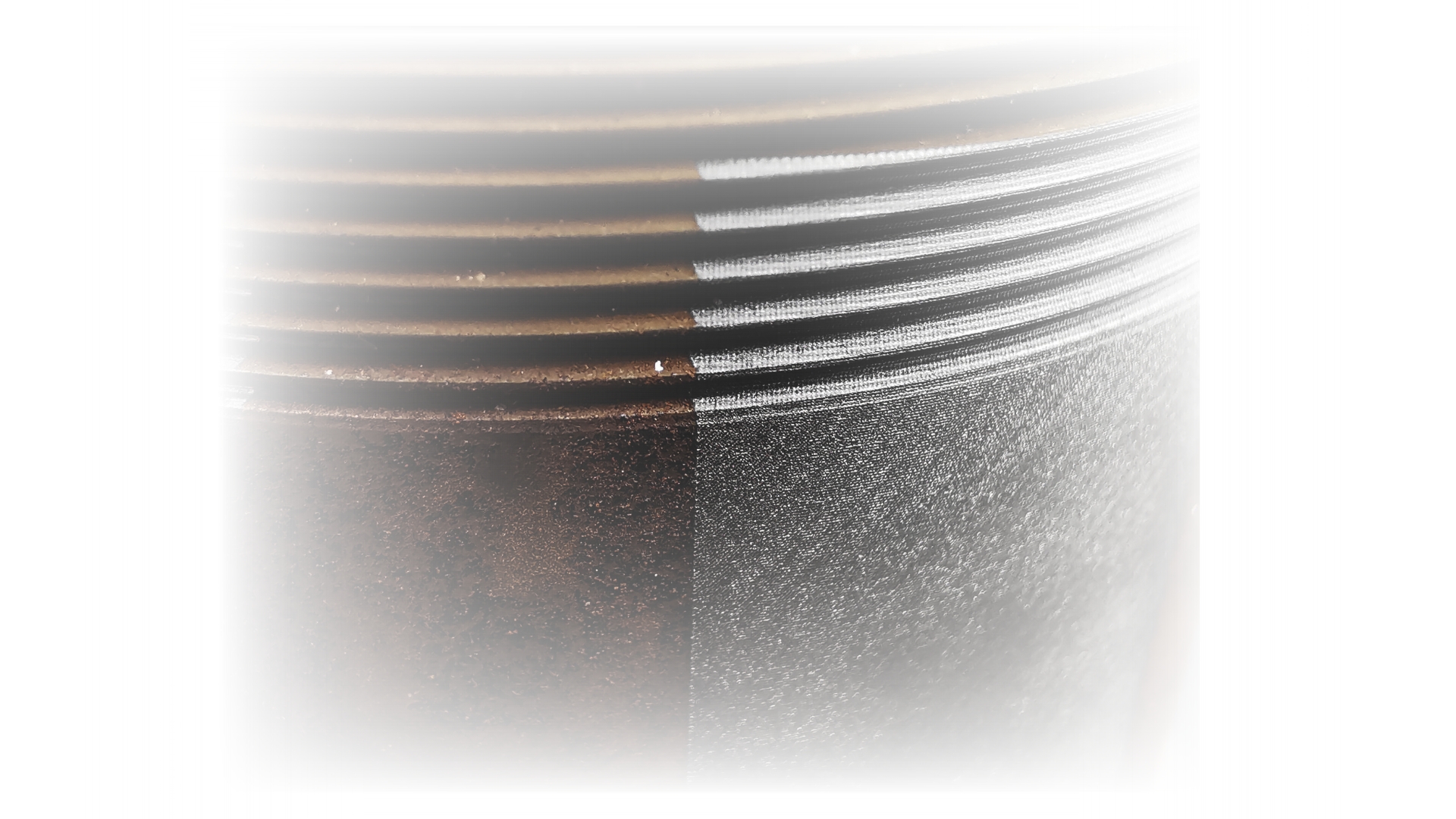

Sandblasting and laser cleaning are used to clean, prepare and renovate surfaces. Both technologies have their advantages and disadvantages.

Sandblasting:

One of the advantages of sandblasting is that it can quickly and efficiently remove rust, paint and other contaminants from large surfaces. In addition to its cleaning effect, it can also be a good choice for surface preparation, as it leaves a rough surface.

As with all technologies, this process has its drawbacks, a large amount of dust and waste is generated, which poses risks to the environment and human health. It can not only improve the surface, but also damage it, as sandblasting can also wear down the surface. In addition to the full protective equipment, it is also against loud and tiring work.

Laser cleaning:

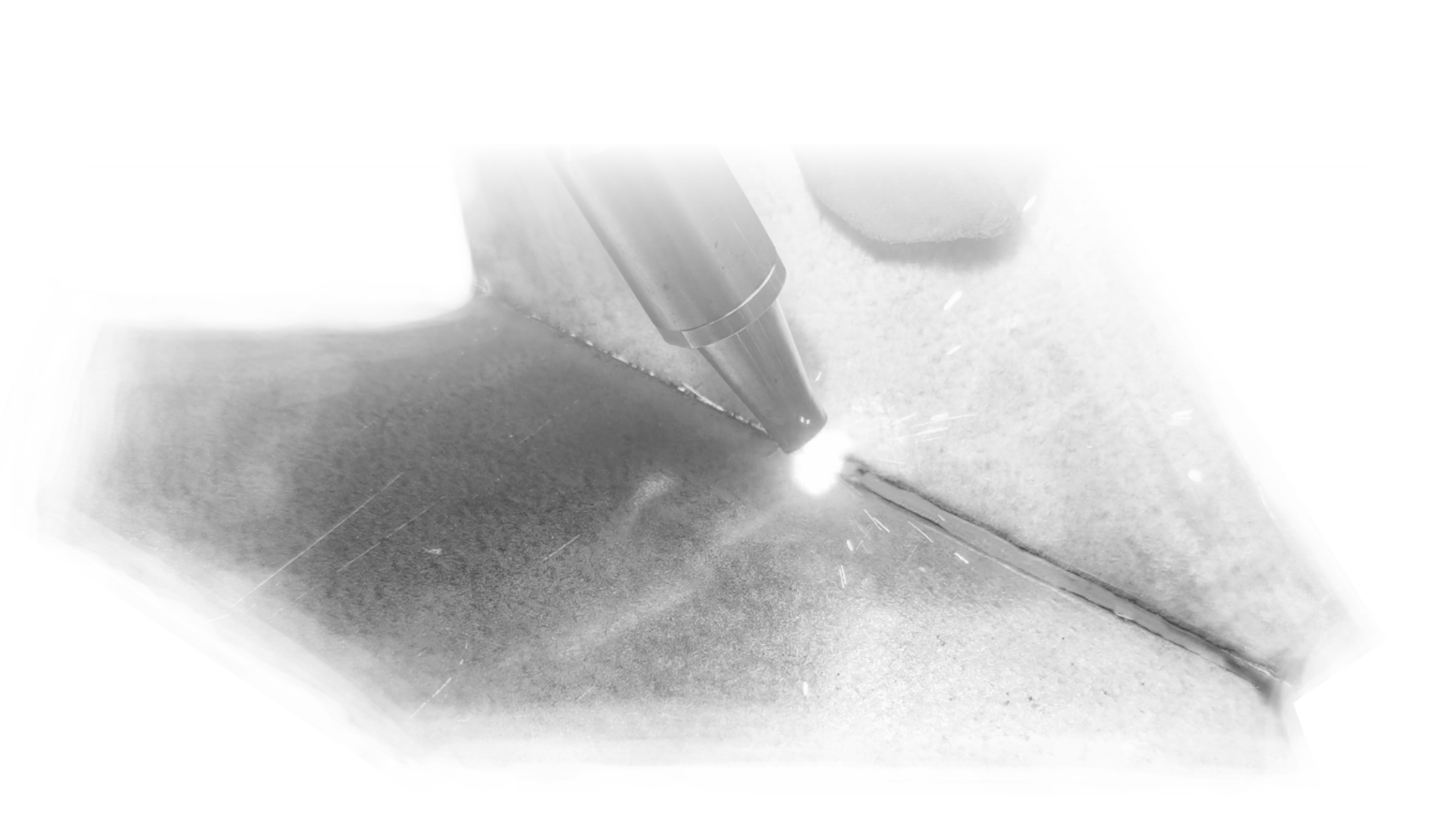

Laser cleaning has many advantages, including micron accuracy, precision and a contact-free work process. It removes dirt with great precision without damaging the raw material. During the cleaning process, little waste is generated, as it turns most dirt into dust or gases, which we can remove from our environment by exhausting it, so it does not have a harmful effect on health either. There is also no need for post-processing before further processing, as it leaves behind a perfect surface.

Laser cleaning also has its disadvantages, it is not the best solution for large surfaces, as it was developed for precise work. The investment cost is relatively high, but with regular maintenance we can increase the duration of our laser equipment.

It is mostly used for rust removal and paint removal, on workpieces where the surface is coated after cleaning. (e.g. car rims, vehicle chassis, building steel structures, etc.) Ideal choice for both pre- and post-treatment of welding seams.

It can be used to clean and remove certain surfaces. fiberersx laser cleaners are precision tools. They easily clean workpieces and tools from the hardest rusts, oxides, deposits, oils and paints, etc. So it is a perfect solution for cleaning tools and parts, because there is no loss of material during the cleaning process, which is an important requirement in industries. During laser cleaning, the surface remains undamaged, in contrast, this is not guaranteed with a traditional cleaning process. At the same time, the process is extremely fast, thus improving productivity, which also guarantees greater profits in the long run.

In summary, the technology is suitable for the removal of rust, oil, grease, graphite, various oxidations, paints and coatings, as well as for the decontamination of raw metal materials.

Laser cleaning in the field of industries:

Laser cleaning is an innovative technology used to clean and prepare surfaces. It is used in many industries including the automotive industry, aircraft manufacturing, electronics industry, railway manufacturing, and plastic injection molding. It has many advantages over mechanical, chemical or other cleaning methods. Main areas and applications:

Removal of rust and oxide layers:

Provides an effective method for removing rust and oxide layers on metal surfaces. It removes dirt without damaging the surface.

Removal of paint and coatings:

Removes varnishes, paints and other coatings quickly and efficiently from metals, plastics or composite materials. This type of procedure is primarily important for the automotive and aerospace industries, as surface preparation is important before painting or coating.

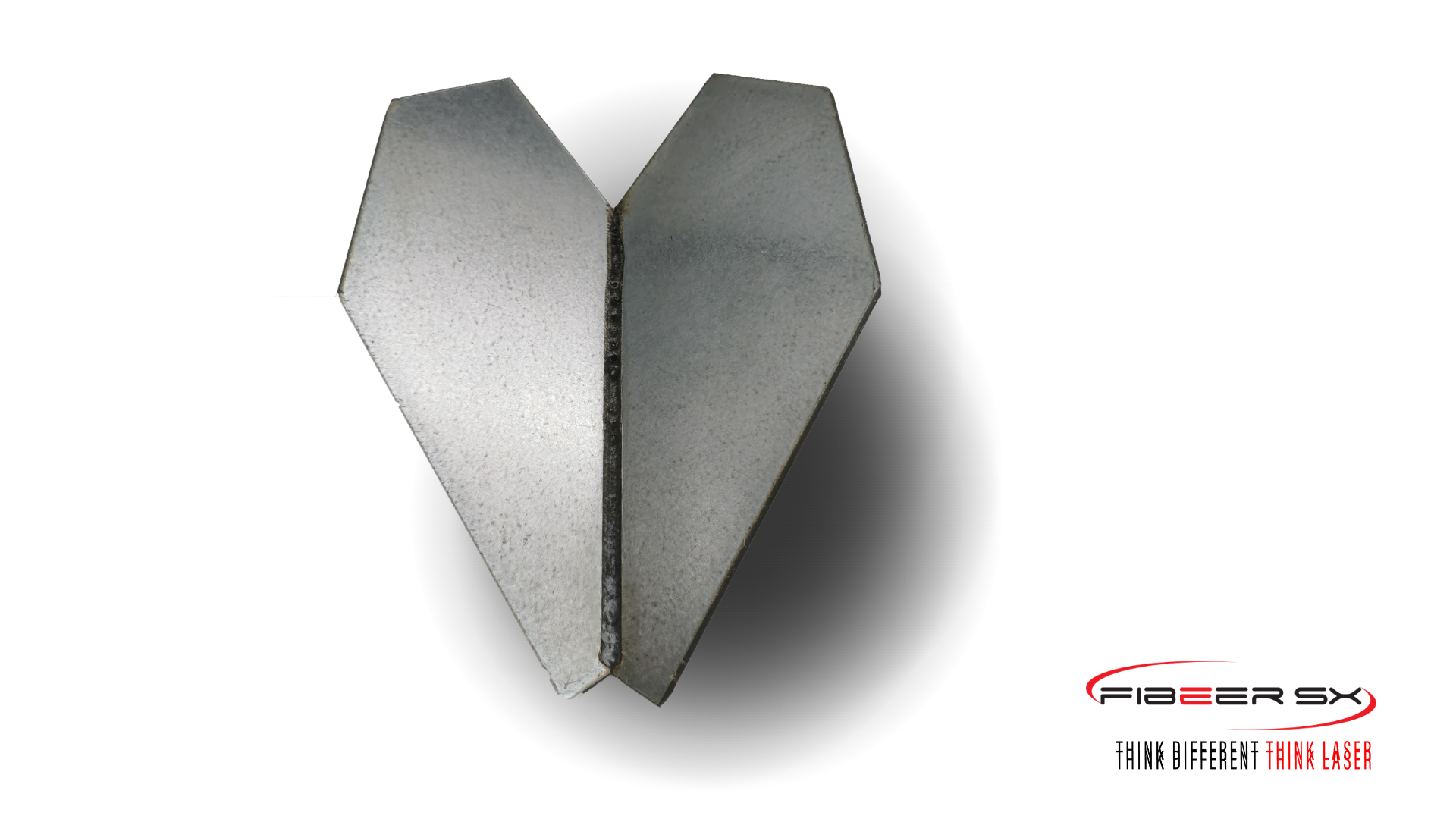

Preparation of welding seams:

Preparation and cleaning of welds increases the quality of the weld by removing micron impurities and oxide layer.

Cleaning injection molding tools:

Due to its precision, it can also be used for cleaning plastic injection molds and tools. It can effectively remove dirt from a specific location without damaging the fine details of the tools.

Cleaning electronic components:

Traditional cleaning methods are not precise or efficient enough to clean microelectronic components, on the other hand, precision laser technology removes dirt with precise and targeted cleaning.