Laser cleaning is a modern, environmentally friendly technology that is used in more and more industries to remove dirt, oxide layers, paints and other unwanted materials. Using the energy of the laser beam, it removes layers of dirt in a targeted manner, without material loss. This non-contact method is not only effective, but also safe, as it avoids the use of chemicals and abrasives, thus protecting health and the environment.

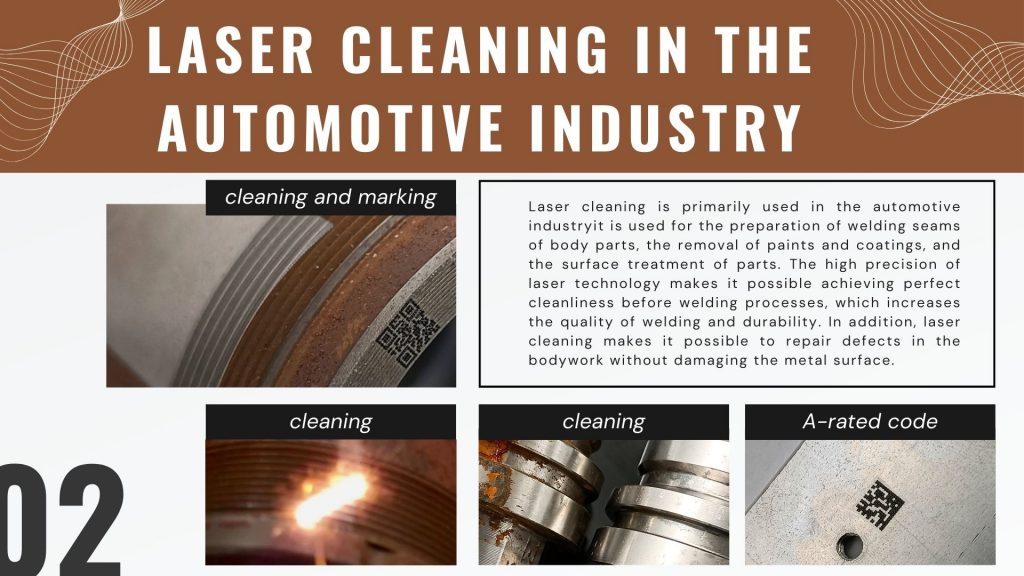

Laser Cleaning in the Automotive Industry

Laser Cleaning in the Automotive Industry

Laser cleaning is primarily used in the automotive industryit is used for the preparation of welding seams of body parts, the removal of paints and coatings, and the surface treatment of parts. The high precision of laser technology makes it possible achieving perfect cleanliness before welding processes, which increases the quality of welding and durability. In addition, laser cleaning makes it possible to repair defects in the bodywork without damaging the metal surface.

Laser Cleaning in the Plastic Industry

In the plastics industry, laser cleaning is primarily used to clean molds and tools. Laser technology makes it possible to remove dirt from plastic molds without damaging the surface of the mold, thus extending their life. In addition, laser cleaning is also suitable for preparing plastic surfaces before painting or other surface treatment procedures.

Laser Cleaning in the Electronics Industry

In the electronics industry, laser cleaning plays a critical role in cleaning circuits, semiconductors and other delicate electronic components. The precision of the laser beam makes it possible to remove dirt without damaging sensitive components. The technology is particularly useful for cleaning miniature parts where conventional cleaning methods cannot be used.

In the electronics industry, laser cleaning plays a critical role in cleaning circuits, semiconductors and other delicate electronic components. The precision of the laser beam makes it possible to remove dirt without damaging sensitive components. The technology is particularly useful for cleaning miniature parts where conventional cleaning methods cannot be used.

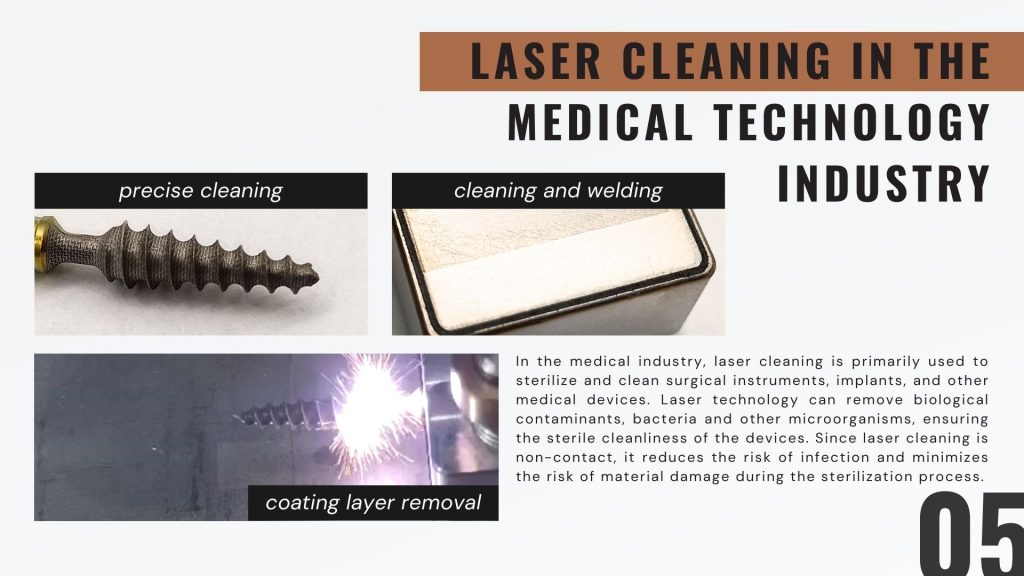

Laser Cleaning in the Medical Technology Industry

In the medical industry, laser cleaning is primarily used to sterilize and clean surgical instruments, implants, and other medical devices. Laser technology can remove biological contaminants, bacteria and other microorganisms, ensuring the sterile cleanliness of the devices. Since laser cleaning is non-contact, it reduces the risk of infection and minimizes the risk of material damage during the sterilization process.

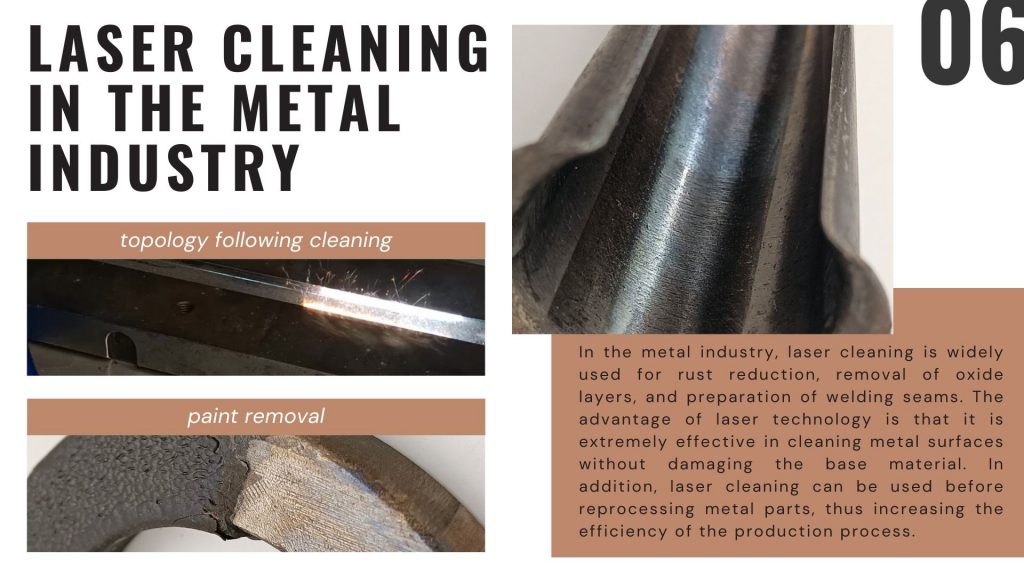

Laser Cleaning in the Metal Industry

In the metal industry, laser cleaning is widely used for rust reduction, removal of oxide layers, and preparation of welding seams. The advantage of laser technology is that it is extremely effective in cleaning metal surfaces without damaging the base material. In addition, laser cleaning can be used before reprocessing metal parts, thus increasing the efficiency of the production process.

Summary

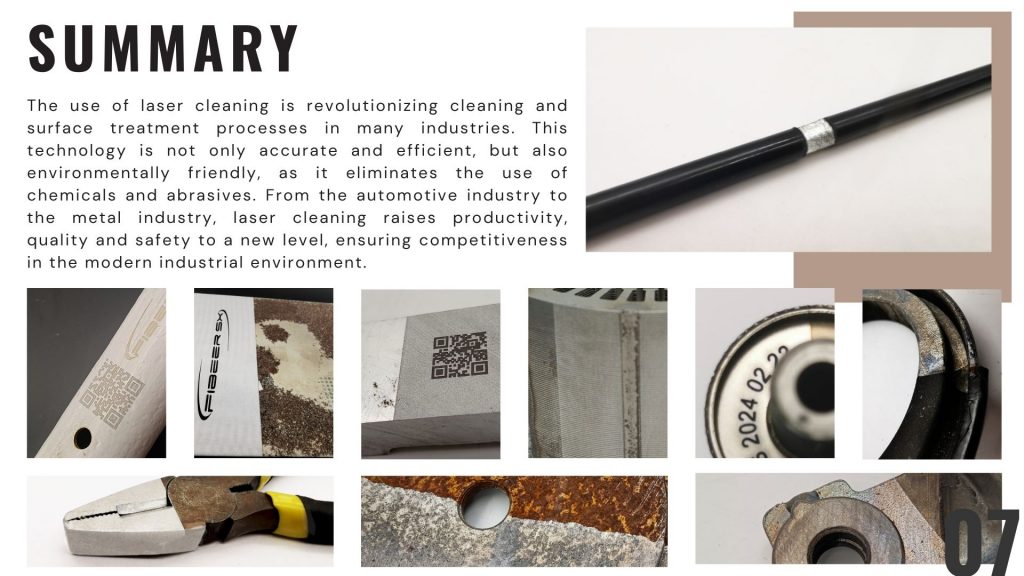

The use of laser cleaning is revolutionizing cleaning and surface treatment processes in many industries. This technology is not only accurate and efficient, but also environmentally friendly, as it eliminates the use of chemicals and abrasives. From the automotive industry to the metal industry, laser cleaning raises productivity, quality and safety to a new level, ensuring competitiveness in the modern industrial environment.